Commercial reverse osmosis systems are the reliable turnkey solutions for various commercial and residential applications. Water bottling plants, steam boilers, garden centers, restaurants and many other types of businesses take advantage of their excellent performance and durability.

New unique ECONNECT function turns commercial reverse osmosis system for water purification into modern smart device.

Equipment

- Grundfos® CM 3-14 pump

- 300 psi membrane vessels

- BB20 sediment prefilter

- Electrical panel with Ecosoft controller

- Danfoss solenoid valves

- Piping, instrumentation

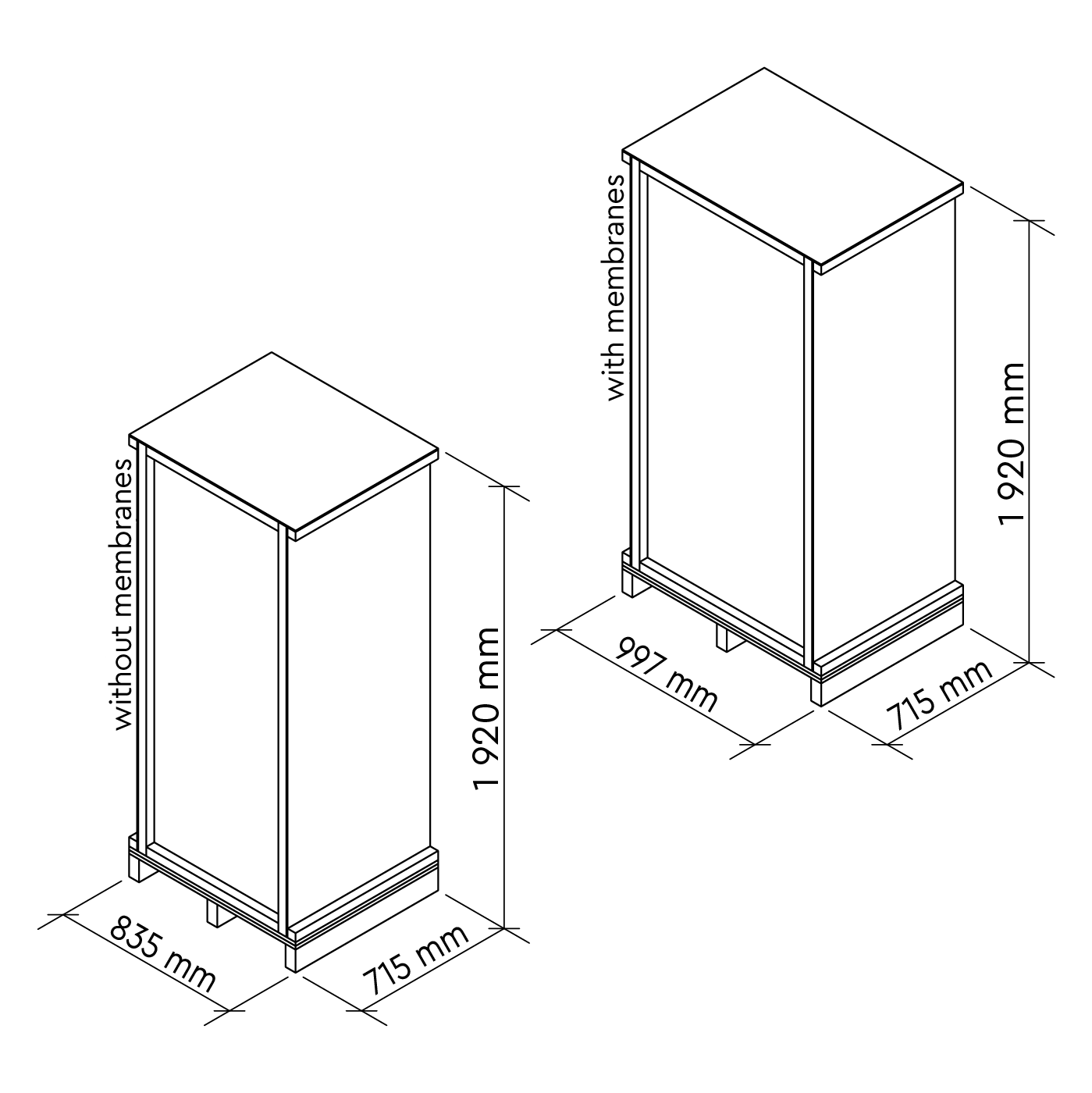

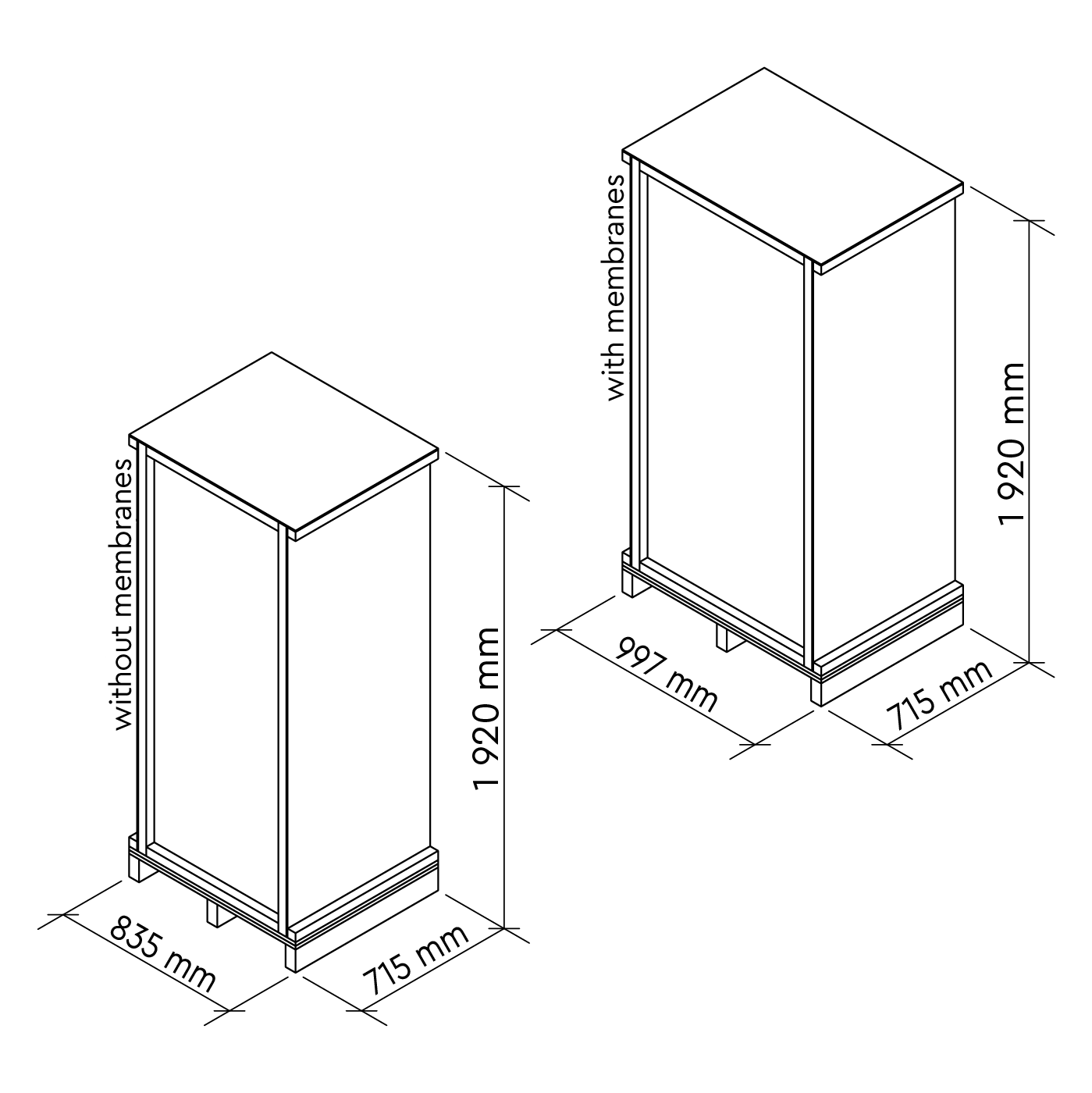

- Steel frame

- Wooden crate

- PP melt blown sediment filter, 5 micron

Options

- Filmtec™ ХLE-4040 / LCLE-4040 or Ecosoft ELP-4040 membrane

- Dosing pump for antiscalant

- Versatile set for raw water blending (120...1080 L/h) or permeate flushing

Connections:

- influent water: 1"

- permeate: 1"

- concentrate: 1"

- antiscalant dosing port: ½″

- raw water blending port: ⅜″

- permeate flushing input port: 1"

Specifications

- Permeate capacity*: 1000 L/h

- Permeate recovery**: 75%

- Maximum TDS: 3000 mg/L

- Influent flow demand

- 1300…1500 L/h (service)

- 3000…4000 L/h (rinse) - Operation pressure: 8…12 bar

- Maximum pressure: 14 bar

- Electrical requiremnt: 230 V, 50 Hz (1 ph)

- Electrical power: 2.0 kW

- Prefilter rating: 5 μm

* depends on feed water TDS, temperature, and permeate recovery

** for low scaling/fouling water

Feed water requirements

- Influent water temperature: +5...+40 °С

- Residual chlorine, max: 0.1 mg/L

- Hardness: up to 3 meq/L (150 mg/L CaCO₃)

- Iron: up to 0.1 mg/L

- Manganese: up to 0.05 mg/L

- Silicate: up to 20 mg/L

- Chemical oxygen demand, max: 4.0 mg О₂/L

- Hydrogen sulfide: none

The limitations may be exceeded if using antiscalant, oxygen scavenger, or other RO chemical pretreatment.

Controller ОС 6000 provides best possibilities for professional maintenance:

— measures flow rate and volume of purified water;

— controls quality of feed water and treated water;

— purified water discharge mode;

— remote update of firmware.

Applications

- Steam boilers

- Heating and cooling circuits

- Breweries and beverage production

- Livestock and poultry farms

- Glazing factories

- Laundry and car wash